Adding Production: #

- To add production go to Manufacturing -> Add Production

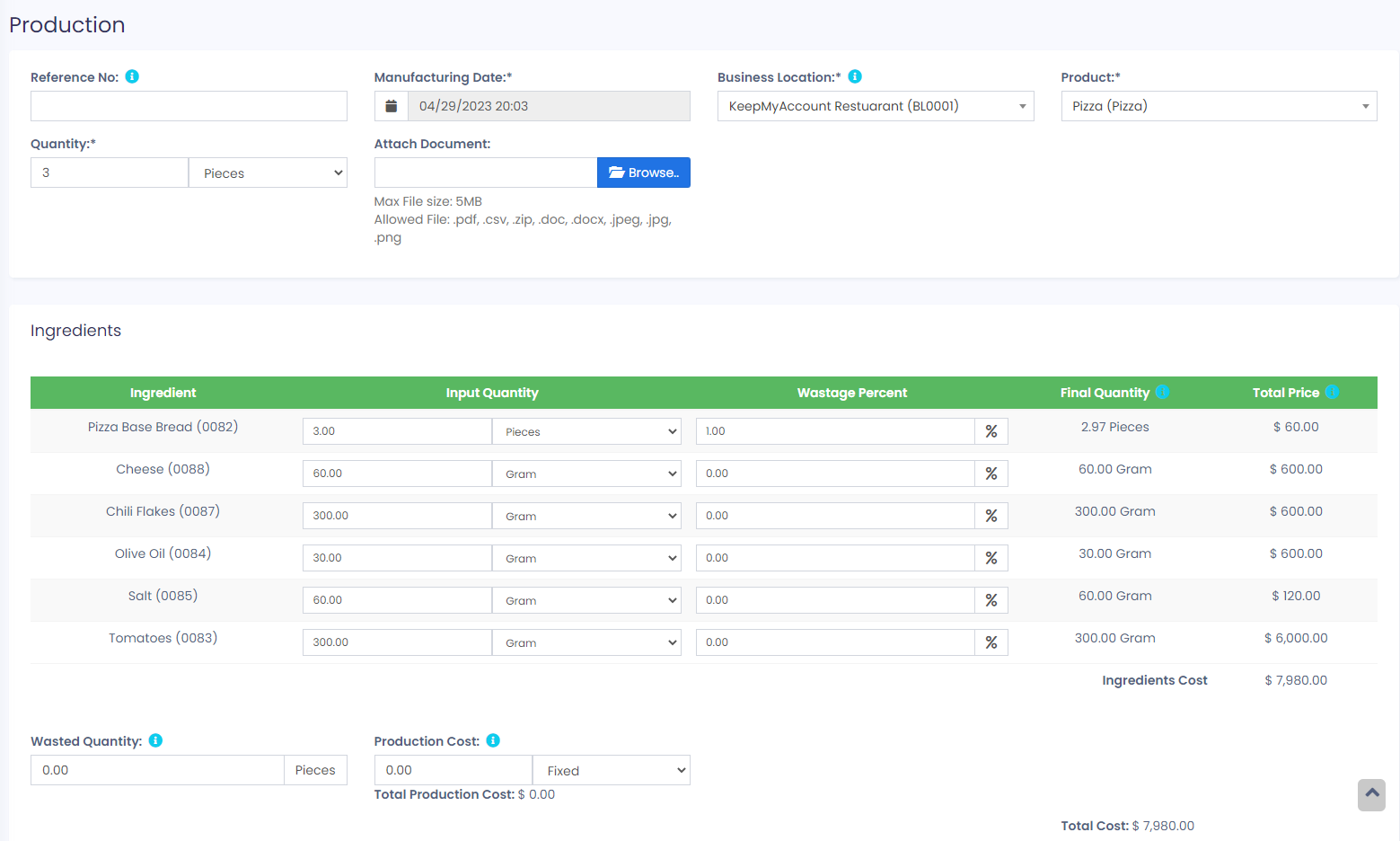

- Reference No: Optional reference number, you can keep it blank to auto-generate it.

- Business Location: Select the business location where production is done. Raw ingredients stocks will be deducted from this location & final manufactured product stock will be added to this location.

- Product: Select the product for manufacturing. based on the selected product it will display all the Raw ingredients from the recipe added.

- Quantity: Quantity of a final product to be manufactured. Based on this the Raw ingredients quantity will be calculated from the recipe.

- Input Quantity: Input quantity of raw ingredients that will be used for production.

- Wastage Percent: Waste percentage of raw ingredients. For example, if you took Cabbage 1 KG, and 200 grams is wastage then the wastage percentage is 20%, so 800 grams will be the final quantity.

- Final quantity: Input Quantity – Wastage Percent

- Wasted Quantity: Wastage quantity of final product for any reason.

- Production Cost: Check the production cost as described below.

- Finalize checkbox: Check this checkbox to finalize the production, this will remove the stock of raw ingredients & add stocks for the manufactured products. After finalizing the production cannot be edited.

Changes in Material(Item) Quantity during Production: #

When production is done for a product, the quantity of raw materials gets reduced.

For example, for adding production of 1 packet of Chocolate Milk Shake. The raw materials used here are 1 packet of milk and 1 packet of bar chocolate.

When production is added for this product(Chocolate Milk Shake) and finalized, the following changes happen in product quantity.

- The quantity of milk gets decreased by 1 packet.

- The quantity of bar chocolate gets decreased by 1 packet.

- The quantity of Chocolate Milk Shake gets increased by 1 packet.

NOTE: These changes happen for just one time when the production is added.