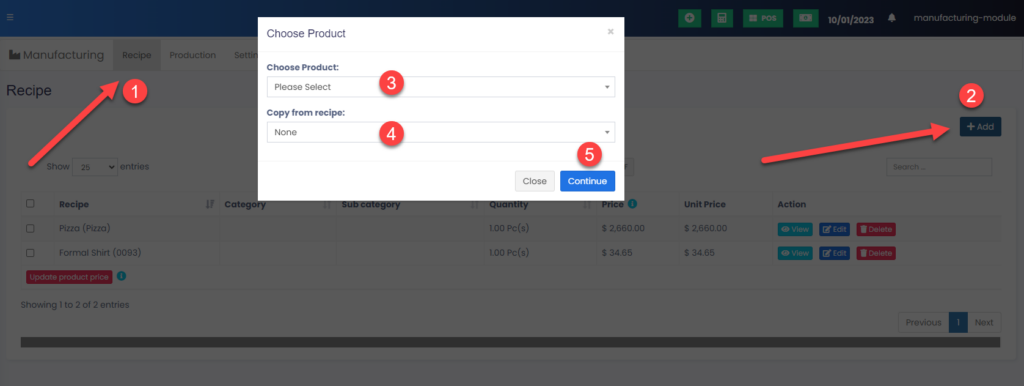

Creating Recipe: #

- To add a new recipe, go to Manufacturing -> Recipe

- Click on the ADD button, it will open a popup,

- Choose Product: Select the product to which you want to add a recipe.

- Copy from recipe: (optional) Choose the product whose recipe will be copied to the chosen product. You can use this option to quickly copy a recipe from another product & make small changes as required.

- Then continue to add the ingredients of this recipe.

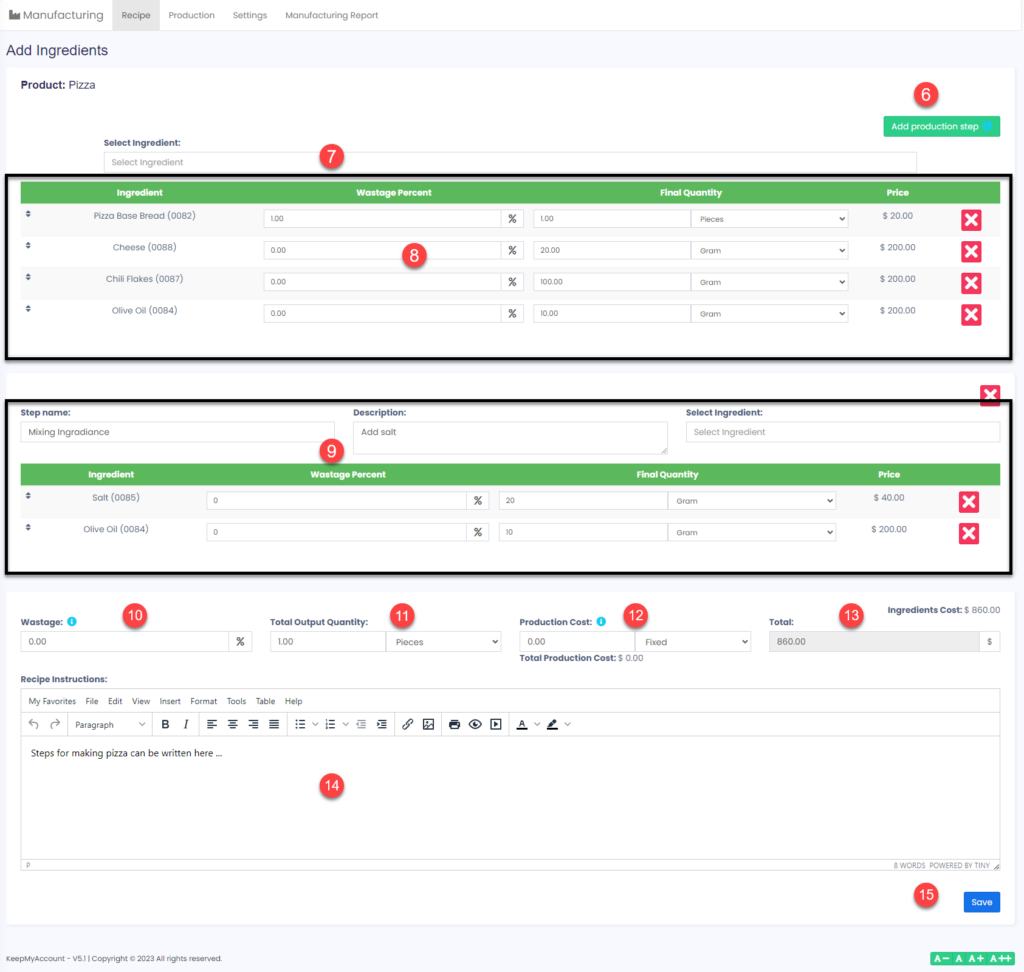

- If you need to add multiples steps like ( Step :9 ) you can add the steps from here.

- Add the Raw ingredients one by one from the search field , Raw Ingredients are taken from the list of products. You can mark a raw ingredient as “Not For Sale” if it is not used for selling individually. For example, Some Raw ingredients like butter can be sold, some cannot be. check this docs how to create product .

- you can all the added ingredients here and change quantity and wastage percentage ( The wastage percentage mentioned here is wastage for the raw ingredients which happens when the ingredient is cleaned, for example in cabbage some % is wasted when leaves & stems are removed. If the raw materials you’re using don’t have waste you can keep it 0 %, which is the default. )

- if you have multiples production steps, add the step name, description after select the ingredients one by one

- Wastage %: Enter the wastage for the final product which can happen because of bad quality or other reasons.

- Total Output Quantity: Output quantity for which you entered the recipe.

- Production Cost: Check the production cost as described below.

- Total:

- Recipe Instructions: Steps to be followed for the production of the final product from ingredients.

- Save the Recipe.

Production Cost: #

- Fixed: If the cost is fixed then a fixed amount will be used as production cost.

- Percentage: If percentage then the percentage of ingredients cost is taken as production cost.

- Per Unit: In this case, the total production cost is multiplied by the total output quantity